Modern production equipment is designed for high productivity and quality. To achieve these aims, it is of critical importance that all production parameters are complied with exactness.

For this reason force measurement systems are used in, for example, the steel, aluminium, paper and plastic industries to measure strip and web tension, among other applications.

Force measurement systems offer the highest levels of precision as well as reliability, flexibility and long service life for your quality management purposes. They consist of at least one force transducer and one electronic evaluation unit.

Precise, Dynamic, High-Speed Response

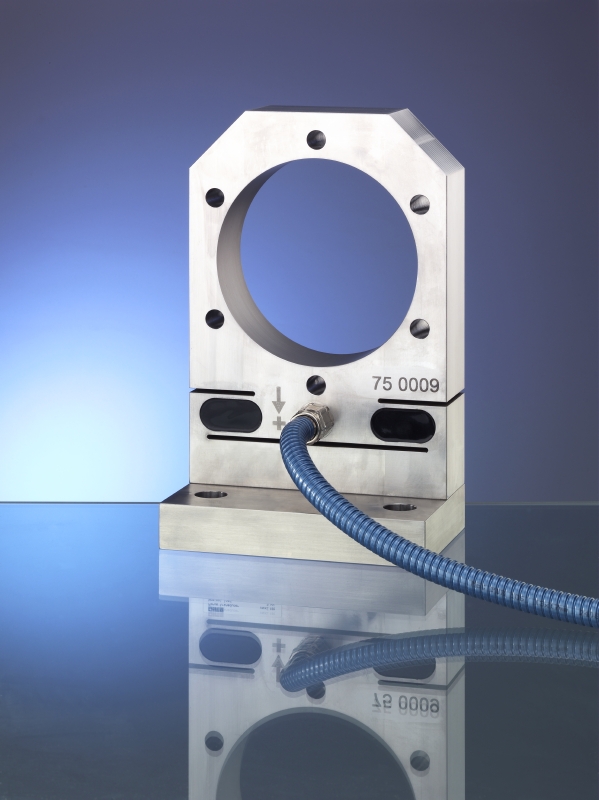

The force transducers – preferably made of a steel or aluminium bellows – are manufactured to customer requirements.

The bellows is equipped with wire resistance strain gauges and can be deformed elastically at pre-defined points, the measurement zones, when a force is exerted on it. This changes the resistance value of the strain gauges, which is then converted to a voltage change.

Features of force transducers:

- High dynamics and precision as well as fast reaction to force changes.

- The integrated calibration signal makes a reference measurement on site unnecessary. This facilitates commissioning.

- Manufacturing in accordance with the customer’s specific requirements ensures easy installation and simplifies commissioning.

- High overload capacity (standard up to eight times the nominal load), optionally up to 20 times the nominal load.

Force transducers in wire resistance strain gauge technique are passive systems that do not generate their own signals. An electronic evaluation unit is therefore needed to capture and evaluate the force signals.

Strip Tension Measurement System

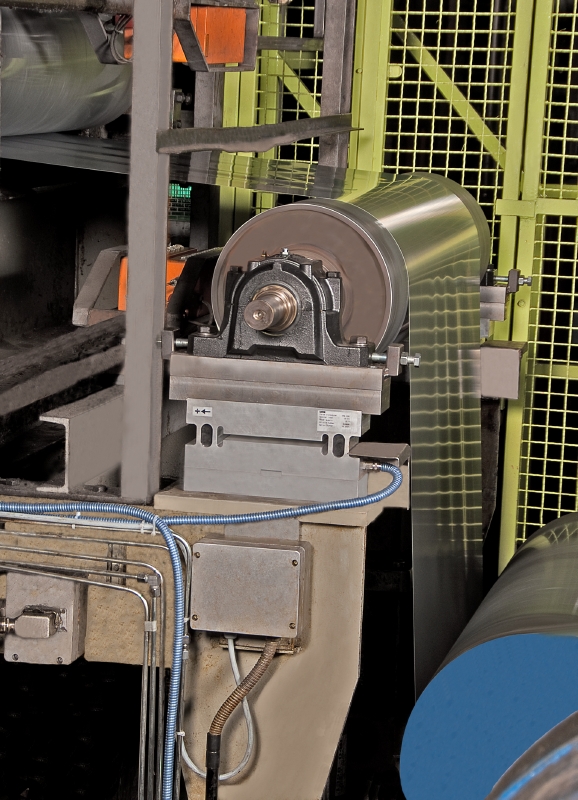

It is necessary in the continuous production of steel, aluminium, paper or foil to measure the tension in the strip at various points of a production line. Only then it is possible to achieve a constant standard of quality.

Since it is not possible to measure the tension directly in the strip, it is determined indirectly. To this end, the strip is diverted around a deflection roller and the resultant bearing reaction forces are measured.

Measuring Principle to measure these forces, force transducers are inserted between the plumber block of the deflection roller and the machine foundation (one each on the drive and operator side).

The signals of the force transducers are then digitalized in the measuring amplifiers. The strip or web tension is calculated taking the deflection angle of the deflection roller into account. The output signals are made available for further processing.

Force Transducers

Two basic types of force transducer are available for measurement of the bearing reaction forces:

Horizontal Force Transducer, Type HMK. The HMK force transducer is sensitive to forces parallel to the mounting plane of the force transducer.

Vertical Force Transducer, Type VMK. The VMK force transducer is sensitive to forces square to the mounting plane of the force transducer.

Additional properties:

- The support bearing used can be mounted directly to the force transducer without adapter plate.

- The materials used lend the force transducers high spring stiffness, which ensures strip run stability.

The choice of which force transducer is suitable for a particular application depends on various factors, e.g. the mounting position, strip run and the weight force from the weight of the deflection roller.

– For any kind of application that measuring the applied forces are crucial, we have a tailor-made engineering solution based on your requirements. So, please Contact Us and we would be at your disposal.